SHOP for TIRES

Everything You Need to Know About Belt Maintenance and Repair

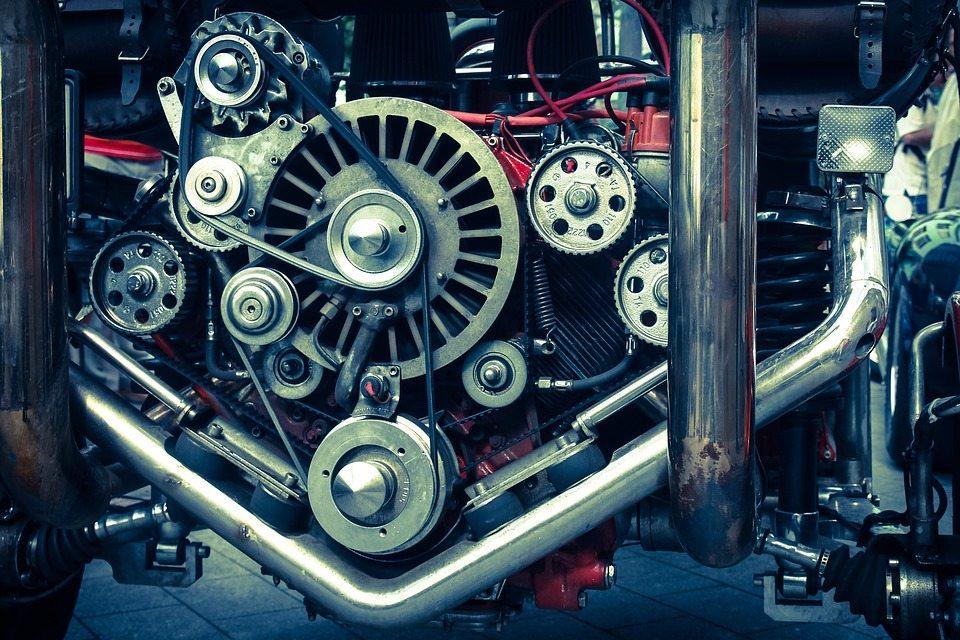

The serpentine belt, also known as the drive belt, is responsible for connecting the alternator, power steering, AC, and other important components to the crankshaft. The crankshaft is part of the engine and provides power to the alternator. The crankshaft may also provide power to the water pump in some cars.

Over time, the drive belt will develop wear and tear because of the heat caused by the engine. Eventually, the belt will break, making steering difficult. For cars in which the water pump is also controlled by the crankshaft, breakage of the drive belt can cause the engine to overheat, which may result in serious problems for your vehicle.

With proper maintenance, you can protect your car from serious damage and save yourself some money on repairs.

Basic Belt Maintenance

To increase the longevity of your car's serpentine belt, there are a few basic maintenance tips you should be aware of.

- Know where your belt is located. The exact location of the serpentine belt may vary depending on the car. For most cars, the belt will be located at the front of the engine. When checking the belt, always make sure the car is switched off and cooled down.

- Your belt should be inspected with each oil change. Mechanics will normally check the belt to ensure no significant damage has occurred. However, checking it yourself is fairly straightforward.

- Make sure the belt is aligned on the pulleys correctly. If the belt slips off the pulleys, your car may not run properly or important components may lose power.

- Check your belts tensioner. The tensioner regulates the amount of tension placed on the belt to make sure it stays on the pulleys. If the tension is loose, the belt can slip off the pulleys and cause components powered by the belt to lose power.

- Know the important rule of thumb. If there are more than three cracks in a one-inch space on the belt, it's time to replace it.

- One belt usually lasts 60,000-100,000 miles. Belts don't need to be changed often unless they are getting old or have sustained damage.

Warning Signs

Make sure you know how to tell if your belt is at risk of breaking. You may want to call a mechanic or check your belt if you notice any of the following warning signs:

- Squealing noise coming from the engine

- Check battery light is on

- Grooves, frays, or cracks in the belt

- Slick or weak spots in the belt

- Rubber peeling off the belt

- Steam or vapor coming from underneath the hood

- Other signs of engine overheating

Replacing a Broken Belt

Repairing worn or damaged belt isn't possible. You'll need to replace the belt rather than attempt to repair it. If you're not familiar with what's going on under the hood, you may want to enlist the help of a mechanic.

If you want to try replacing the belt yourself, use the following instructions as general guidelines. (Remember, every car is different, and changing the belt on certain cars may require special tools.) Changing the belt should only take about 15 minutes.

- Make sure the car is switched off and cooled down before touching any part of the engine.

- Read your belt routing diagram. This may be under the hood or in your car's manual.

- Use a wrench, ratchet, or special serpentine belt tool to release the belt tensioner.

- Remove the old belt from the pulleys.

- Check to make sure the pulleys spin freely.

- Hold the old and new belts up next to each other to make sure they are the same length and width.

- Following your routing diagram, install the new belt. Make sure the grooved side of the new belt is placed against the grooved side of the pulleys. (Your car may or may not have grooved pulleys.)

- Tighten the belt by compressing the tensioner.

- Check your belt's tension. Pull the belt. If it stretches farther than one inch, it is too loose.

- Before starting your car, double check to make sure the belt is properly routed, the belt is placed straight onto the pulleys, and that there is enough tension.

After replacing the belt, keep the hood open and try starting your car to make sure all components have power. Watch the belt to make sure it is rotating properly on the pulleys. If there are any issues, check your routing diagram to ensure you've routed the belt correctly.

Even though replacing the belt is a relatively simple part of vehicle maintenance, consult a mechanic if you have any doubts about the installation. An improperly installed belt can cause major problems for your car.